Grooving in hardened workpiece materials

Grooving in hardened workpiece materials

$220 (USD)

Location:Germany

Available quantity:99

or

Call +1 (305) 951 -7825

Description

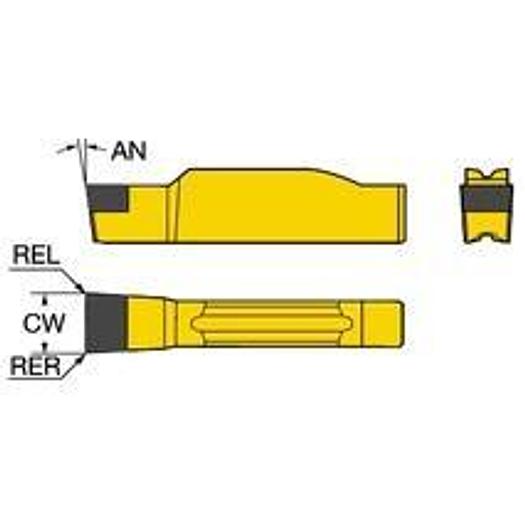

CoroCut® 1-2 cutting system for grooving

- Application Area: TP

- Corner radius, left (REL): 0.2 mm

- Corner radius, right (RER): 0.2 mm

- fnx max: 0.10000000000000001 mm/r

- fnx min: 0.02 mm/r

- fnx rec: 5.0000000000000003E-2 mm/r

- Main clearance angle (AN): 7 deg

- Manufacturer item number: N123J1-0600-0002-GE CB20

- Manufacturer: SANDVIK COROMANT

- IC Code: 18200

- ISO Cutting Tool Material: BL

- Life Cycle Status (LCS): 20

- Upper corner radius tolerance (RETOLU): 0.05 mm

- Upper cutting width tolerance (CWTOLU): 0.02 mm

- Cutting insert size and shape (CUTINT_SIZESHAPE): CoroCut 1-2 -size J1

- Cutting direction (HAND): N

- Grade: CB20

- Chip breaker, manufacturer's designation (CBMD): GE

- Grooving width, nominal dimension (CW): 6 mm

- Substrate Type: CBN

- TMC Order: 1

- Lower corner radius tolerance (RETOLL): -0.05 mm

- Lower cutting width tolerance (CWTOLL): -0.02 mm

- vc max: 125 m/min

- vc min: 120 m/min

- vc rec: 125 m/min

- Material classification level 1 (TMC1): H

- Grooving width nominal dimension C: 6 mm

- Corner radius right RE: 0.2 °

- Grade: CB20

- All ISO application areas: H

Specifications

| Manufacturer | SANDVIK COROMANT |

| Model | N123J1-0600-0002-GECB20 |

| Year | 2024 |

| Condition | New |

| Serial Number | 520 N123J1-0600-0002-GE CB20 |

| Stock Number | . |